+86 0371-69392107 Info@synthe-corp.com Request a Quote

Vacuum aluminum brazing is the process of welding or joining two metal parts by filling or repairing them at a controlled temperature. These metals can be aluminum, known as base metals . Holes and joints are filled with brazing alloys or filler metals that have a low melting point. A key point in this process is to obtain a filler metal with a lower melting point than the base metal. Otherwise, the base metal itself will melt as it is heated and will change the shape of the metal.

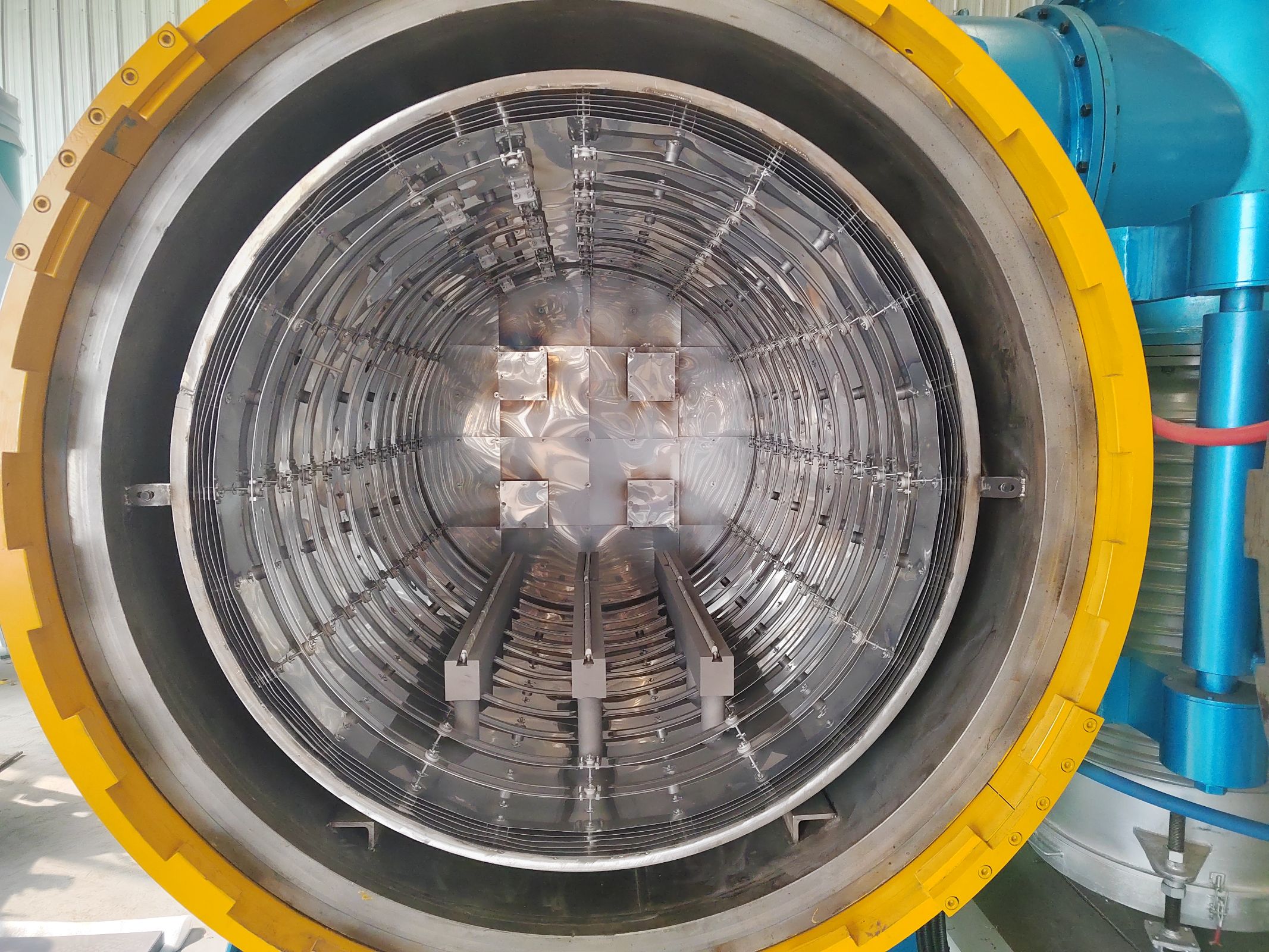

Vacuum Aluminum Brazing Process Guide.

In this process, the heat generated by the gas is used to melt the filler metal to fill or repair cracks, and in some locations, vacuum aluminum brazing is more effective than the original. There are no special requirements for professional training in vacuum aluminum brazing. You can easily braze aluminum with some common welding knowledge. Some basic principles should be followed to get better results.

1. If the base aluminum metal is flat, the brazing process will produce a strong joint bond.

2. Thinner base metal requires extra care in temperature control as uncontrolled temperatures may burn the base metal.

3. brazed aluminum base metal surfaces should be cleaned to obtain stronger joints and repairs. At room temperature, aluminum metal surfaces are covered with oxides through an oxidation process.

4. The vacuum aluminum brazing process requires less equipment, such as argon shielding gas, gloves and spools of wire are not required.

5. Brazing aluminum is a very simple process, but brazing other metals such as titanium and copper requires some innovative process steps.

6. Silicon or zinc in the brazing filler material allows it to melt at lower temperatures, during which this excess metal evaporates and the remaining filler metal (e.g. aluminum) begins to fill the cracks.

Advantages of the brazing process.

1. Simple and less risky form of brazing process.

2. The cost of the brazing process is low because less equipment is required.

3. It requires less power than the TIG welding process.

4. No post-processing heat treatment is required.

5. Two different types of metals can be joined.